Our R&D team is working continuously & effortlessly on new innovation and efficient designs for Liquid Nitrogen plants.

Manufacturing of our Liquid / Gas Air Separation Plants is finished with the highest technology using low pressure with lowest power consumption.

We manufacture Italy brand Liquid Nitrogen plants as per European Quality & technology of the highest standards.

We are manufacturers and suppliers of Liquid Nitrogen Plants in India. Our liquid nitrogen plant are being manufactured as per the latest technology & design of the Company ING. L. & A., BOSCHI, ITALY. This technology has been proven all over the world for its working efficiency & trouble free operation.

Our focus is to make world-class products that completely satisfy the requirements of our clients. We pay a great deal of attention to the demands and needs of our customers. We study the weather and working conditions of countries where our maximum users of our air separation products are concentrated. Accordingly, the fabrication is customized so that our products deliver the best performance under specific conditions.

Capacity Range – 20 LITRES/hr to 1000 LITRES/hr (liquid production Of LIN2)

(FOR 100% LIQUID PRODUCTION FOR FILLING LIQUID TANKS)

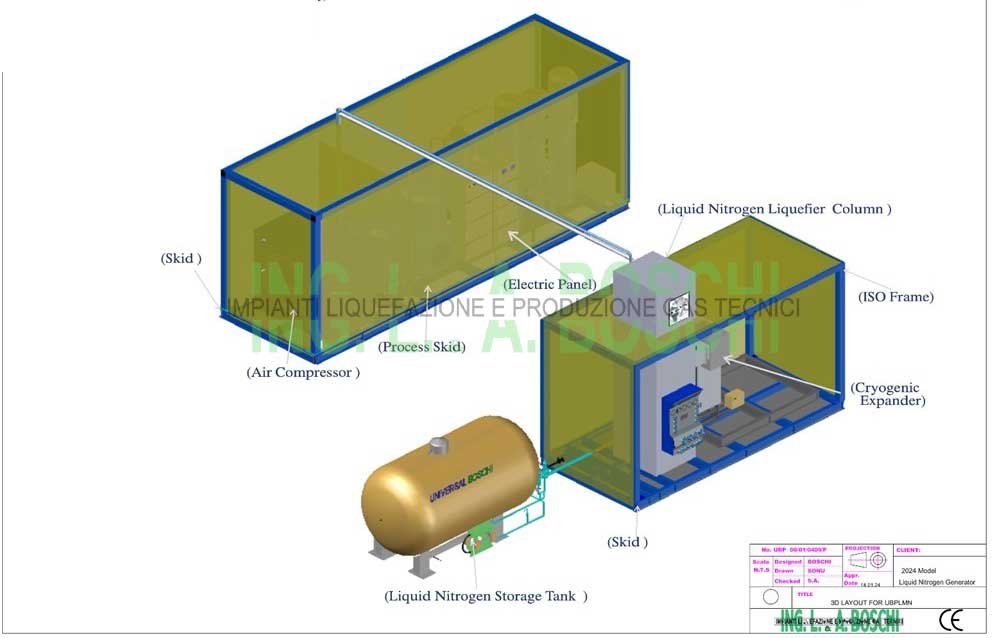

The Liquid Nitrgoen Plant and Generator has been designed according to the different boiling Principle of Purification, Cooling and Liquefaction and based on this principle, an Liquid Nitrgoen Separation Plant can be briefly described by the following processes:

With leakproof stainless steel column and skid mounted version for high purity nitrogen for industrial and scientific applications.

We manufacture and supply liquid nitrogen production plants for small & medium scale industries including food packaging, chemical, medical, etc.

Small and Portable Skid Mounted Liquid nitrogen generator machine used in small scale industrial applications, including laboratory operations, and laser cutting.

Get Setup PriceReliable and Efficient On-Site Plug and Play Liquid Nitrogen Generator plant is produce high purity 99.999% Liquid N2 filling in cryogenic storage tanks..

Get Setup PriceCommissioning & Installations Onsite Fully Automatic Industrial Liquid Nitrogen Plant for Pharmaceuticals, Metal Manufacturing, Oil and gas Refinery, Glass and Mining Industry.

Get Setup PriceGet the Best Price for setting up Liquid Nitrogen Producing Generator System for Largest Industry such as Steel Manufacturing, Food & Beverage Processing Business.

Get Setup PriceWe manufacture liquid nitrogen plant for use in large industries particularly from chemical, steel,pharmaceutical, petroleum, metallurgy, food preparation, cryosurgery, cattle branding, biological sample preservation and food packaging sectors.

UBTL- 100 m3/hr is our product specifically designed & fabricated for meeting the needs of small industries.

Get Setup PriceUBPL- 170 m3/hr is fabricated for meeting the needs of liquid nitrogen in mid-size industries.

Get Setup PriceWe manufacture UBTL- 600 m3/hr model on special orders.It can generate N2 in liquid form.

Get Setup PriceUBTL- 1000 m3/hr is specially designed for large industries with capacity to generate nitrogen in liquid form.

Get Setup Price| MODEL | PRODUCTION IN M3/HR | PRODUCTION LITERS/HOUR | PURITY |

|---|---|---|---|

| UBTLN-50 | 50 | 73 | 99.99% |

| UBTLN-100 | 100 | 145 | 99.99% |

| UBTLN-200 | 200 | 218 | 99.99% |

| UBTLN-300 | 300 | 435 | 99.99% |

| UBTLN-400 | 400 | 578 | 99.99% |

| UBTLN-500 | 500 | 724 | 99.99% |

| UBTLN-1000 | 1000 | 1440 | 99.99% |

| UBTLN-1500 | 1500 | 2171 | 99.99% |

| UBTLN-2000 | 2000 | 2894 | 99.99% |

| UBTLN-3000 | 3000 | 4341 | 99.99% |

| UBTLN-4000 | 4000 | 5788 | 99.99% |

| UBTLN-5000 | 5000 | 7235 | 99.99% |

Atlas Copco’s ZH range is a superior centrifugal air compressor series available in the market. The compressor provides unique features fulfilling customer expectations of low installation, operating, and maintenance costs. It is considered the most advanced compressor with high reliability and user-friendly interface. It packs high power with great efficiency guaranteeing uninterrupted air supply. It provides compressed air at 7.5 bar after removal of contaminants.

Chilling unit is supplied with air coils fitted inside the circular tank and base mounted on the skid. The unit contains Freon evaporation coils inside the tank with inlet and outlet connections to Freon unit with sealed compressors of Hitachi/Mitsubishi, Japan brand, Danfoss Controls Expansion valve and digital panel.

Purification unit is used for removing impurities present in the atmospheric air. Impurities such as oils traces, moisture, and carbon dioxide are eliminated. However, purification unit comprises of the following components:

Air coils with M.S. Tank to cool air after the Air Compressor

Air coils in two separate chambers in tank to Provides extra cooling by waste nitrogen

It consists of pressure vessels with drain valves for removing condensate from the process air at regular intervals of time. Two separators are provided.

This consists of shell and tube type system. The air is chilled by Freon evaporative coils or by the evaporative cooling of Nitrogen optionally. This system cools the process air to 12°C which is necessary for removal of moisture from the process air.

It consists of vessel packed with alumina balls with special filters at inlet and outlet. This is used to remove any oil traces from the process air.

Complete with 2 vessels, reactivation heater complete with Molecular Sieve designed for process skid mounting.

We provide cryogenic type air separation unit complete with connected pipes, supports and proper internal connections. The column is fabricated with the cryogenic grade stainless steel and argon welding.

It forms an important part of the column and is made with highest quality stainless steel. Two sets of heat exchangers are supplied. Type of the equipment is multi-pass and is totally designed and manufactured with ING L A Boschi Italy technical know-how.

It is an extremely crucial part of the air separation that is fabricated with high in-house expertise for yielding high efficiency and reliability. High quality cryogenic stainless steel is used in the construction. Construction is completed with ASME standards.

One set of high quality condenser is supplied with the liquid N2 plant. Liquid nitrogen is deposited at top of the condenser. It is made with ASME standard materials for long durability and reliability.

One set of sub-cooler is provided at the time of installation. High quality materials fulfilling ASME standards are used in the fabrication of the component.

Instrumentation of panel of Cold is finished with world-class materials. Equipment used in the construction of the material is sourced only from our approved list of European vendors. It consists of the following components:

Cryogenic expander is hydraulically operated for providing automatic control of pressure and temperature. It is fitted with a ball type valve at the inlet and outlet to ensure hassle-free working for long durability and reliability. It is supplied with complete electric motor and starter.

Liquid nitrogen pump is important piece of equipment provided with cylinder filling systems. The pump takes nitrogen from the condenser of the column-cold box. Then, it compresses liquid nitrogen to pressure between 150 and 200 bar that moves through a gas vaporizer inside the cold box-column automatically converting liquid N2 into high pressure nitrogen gas for cylinder filling. However, it must be noted that it incurs no loss of purity and is bone dry since there is zero contamination.

We are leaders in manufacturing and supplying liquid nitrogen filling tanks that industries or businesses use to store nitrogen. Manufacturing of liquid nitrogen storage tanks is completed with ASME certified materials and internationally reputed quality standards. It is double walled comprising of inner and outer vessels. Typical cryogenic storage tank vessels contain insulating materials for ensuring insulation from the surrounding heat. The space between the vessels is completely vacuumed so that there is least evaporation.

We manufacture liquid nitrogen storage tanks with capacity ranging from 200 litres to 1, 50,000 litres. Cryogenic storage tank is fitted with a cold convertor for pressure build up which is connected with an automatic pressure build-up regulator. Being a leading manufacturer of liquid storage tanks, we use sturdy materials with stringent quality control. Our storage equipment is reliable, durable and easy to operate. Notably, we employ a pressurizing system that increases pressure when liquid nitrogen is loaded into the tanks or on to the gas line vaporizer. Since the opening of top and bottom filling valves is regulated by the pressurizing system there will be no change of pressure during liquid delivery. As a result, adequate supply of liquid nitrogen will be available for vaporizer.